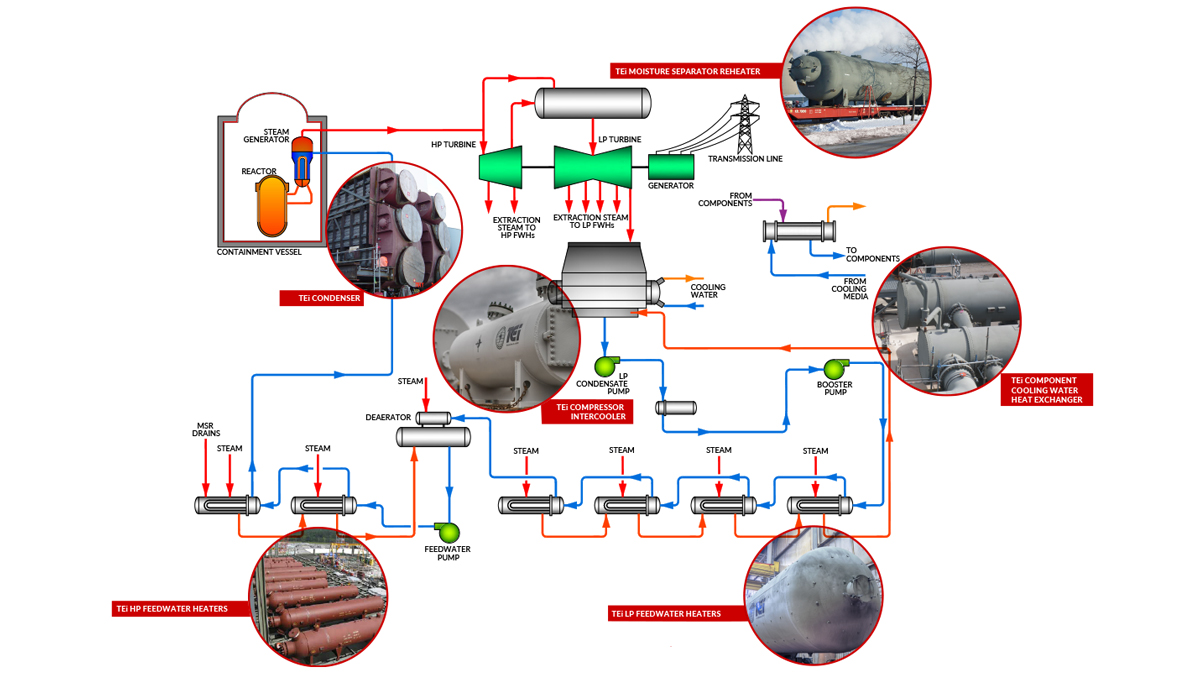

Nuclear Power Plant Equipment

Design Solutions For All Your Nuclear Heat Transfer Equipment

Moisture Separator Reheater (MSR)

TEi has provided complete vessels for new and existing plants in addition to internal replacements and performance upgrades on many of its competitors’ designs. Independent from any Turbine Supplier TEi has references and designs for all orientation of MSR, be it vertical, horizontal, multi stage or integral. In recent years TEi is unrivalled in its ability to improve Moisture Separation efficiency and generate additional reliability and optimum heat rate from existing plants.

An improved MSR system must complement the rest of the upgraded steam plant. Since the MSR interfaces with major plant components, and its optimal performance yields positive effects on the rest of the system, TEi has established the improvement goals differentiators with the following proven results.

Lower Weight – Steam Distribution system / dedicated inlet plenums eliminated

Uninterrupted Moisture Separation & Reduction in Overall Length of MSR Vessel

Lower Pressure Drop – More work through the LP Turbine. This improvement in overall plant efficiency equates to greater MW output of the plant for same thermal (input) power.

Lower TTD (Terminal Temperature Difference) – Higher outlet temperature at the outlet of the MSR which improves the overall plant efficiency producing more work through the LP Turbine.

Improved Moisture Separation – Reduced susceptibility to erosion/corrosion of the latter LP Turbine stages, & improved reliability of the LP turbine.

Condensers

Surface Condenser

Our condenser designs can incorporate enhanced deareation systems, and/or a variety of turbine exhaust options, which can assist in improving plant layouts. We continually address and refine these and other considerations associated with circular designs where space is at a premium. The surface condenser is a critical component in the operation of a steam power plant. Condenser failures can result in forced outages and loss of generation capacity. TEi condensers represent an evolution of advanced technology, offering improved thermal efficiency and advanced mechanical design to reduce forced outages and increase availability.

Surface Condenser, Modular Changeouts

As the innovator in heat transfer technology, TEi provides exceptional modular changeout options for steam surface condensers. Modular changeouts are an efficient alternative to the conventional retube. Existing power plant condensers can be refurbished, redesigned, and even upgraded to meet new performance demands and power requirements. Complete surface condenser retrofits are possible and can offer a multitude of benefits. A surface condenser is critical to the efficient operation of a power plant.

Feedwater Heater

Low Pressure (under 1000 psi)

Each feedwater heater can extract up to 30% of the turbine throttle steam and is designed to specific thermal conditions and manufactured for a singular purpose. The low pressure feedwater heaters play a key role in maintaining efficient, trouble-free operation of your generation facility and the vertical channel down (VCD) designs offer a small footprint, piping economics and simplified bundle access.

High Pressure (over 1000 psi)

TEI’s feedwater heaters are each designed to specific thermal conditions and manufactured for a singular purpose. Whether it be sophisticated designs involving extreme superheat, abnormal flow conditions or dissipation of high energy fluids, TEi has the expertise and experience to offer proven solutions to any design problem. TEi provides innovative and practical concepts to ensure peak heater performance from installation to testing through full or part-load operation.

We offer a multitude of design configurations for desuperheater and drains cooler zones as well as the latest in channel closure techniques. The three most common are listed below:

• Bolted-Gasketed Closure – This economical, gasketed pill box is easily disassembled for full access.

• Seal-Welded Diaphragm Closure – This economical welded closure is leak-proof and easily disassembled for full access. It requires no gaskets.

• Breech-Lock Closure – This widely accepted, quick opening closure provides full access to the tubesheet and structural reliability under varying temperature and pressure conditions.

Heat Exchangers

Closed Cycle Cooling Water (CCW) Heat Exchanger

TEi has successfully supplied numerous optimized BOP and CCW designs for numerous fossil and nuclear power plants undergoing power up-rates and routinely provides solutions for power plants needing to improve efficiencies. With diverse high-quality applications, impressed current & galvanic anodic protection, elimination of potential cross-contamination of fluids, compact construction when designing for fluids with high thermal resistances and can be externally and internally applied, TEi’s mission-critical CCW equipment helps ensure a stable, optimal operating temperature while reducing costs and dramatically improving efficiencies for our customers.

Generator Cooler Heat Exchanger

TEi’s Generator Engine Coolers cool air or hydrogen, which in turn cools the internal components of the motor or generator. These coolers are available in single tube, double tube, plate-fin and fin-tube designs.

Lube Oil Cooler / Turbine Cooling Water Heat Exchanger

The lube oil cooler is to manitain oil temperature of the turbine lube oil by utilizing cooling water through the tubes. TEi provides shell & tube TEMA type heat exchangers for this service.

Motor Cooler Heat Exchanger

TEi’s Motor Coolers cool air or hydrogen, which in turn cools the internal components of the motor or generator. These coolers are available in single tube, double tube, plate-fin and fin-tube designs.