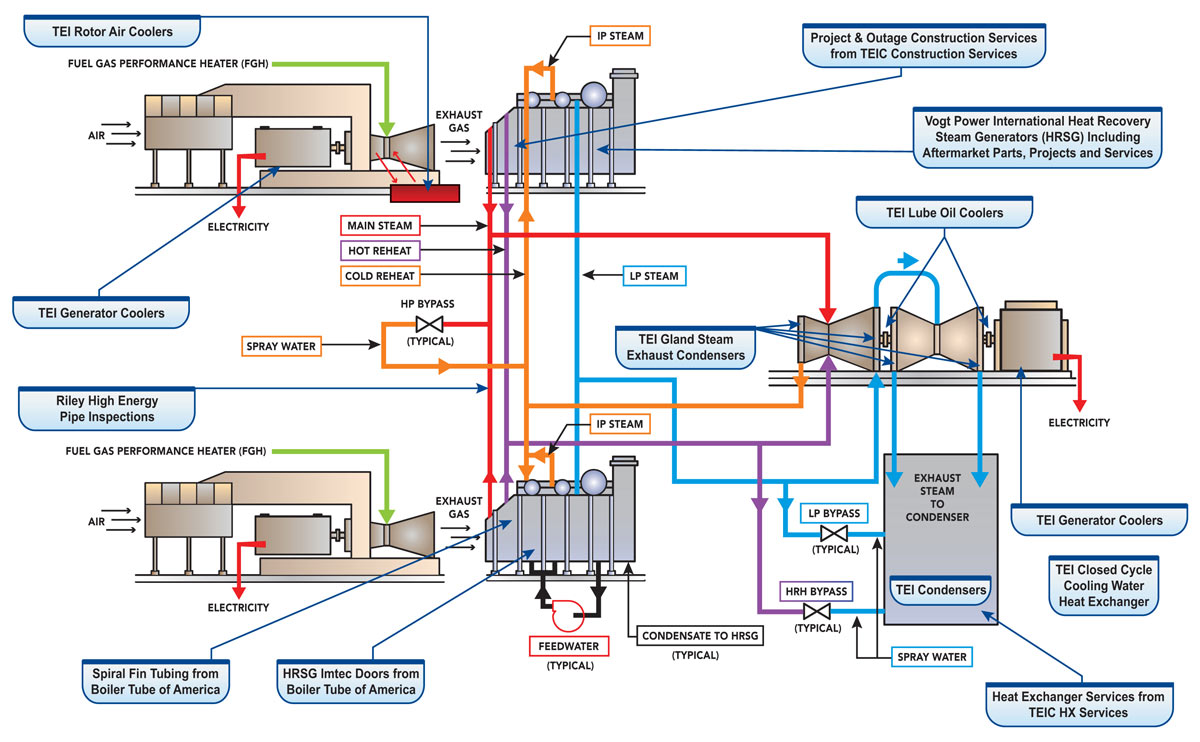

Products & Services For Combined Cycle Plants

Delivering Unmatched Excellence-in-Heat Recovery®

HRSG Designs

Vogt Power’s utility-sized HRSGs are designed to recover and recycle heat energy from gas turbine exhaust. A HRSG produces steam that can be used in a process (co-generation) or used to drive a steam turbine (combined cycle). We offer multiple construction options to meet unique site-specific applications, and we design products to meet codes and standards such as: ASME, TRD, IBR and PED/CE. Whether you need HRSG optimization, service, improved efficiency, inspections, or parts and service, Vogt can handle your requests.

MODULAR STEAM GENERATOR (MSG)

MSG– Modular Steam Generator; sold since the 1960’s, still the best for single wide applications.

The Module Steam Generator is 25–70 MW with a single wide modular design. This option includes standard width designs, 1, 2, or 3 pressure levels, and a full range of supplementary equipment with an accelerated delivery schedule.

| Features | Benefits |

|---|---|

| Designed for HRSGs behind 30-70 MW gas turbines that allow a single gas path width |

Dramatically reduces erection schedule |

ENHANCED CONSTRUCTABILITY SMART (ECS)

The Enhanced Constructability SMART includes all SMART design features with the main steel support structure added to the boxes in a design we call (ECS).

Module Box Features:

• Top & bottom transverse beams are shop installed

• Main columns shop assembled to module boxes

• Top, bottom and side casings are shop installed to module boxes

• No up-righting steel required during installation

• Back to back channels and hanger rods are shop installed

• Piping is shop installed inside module casings

• Manifolds used to minimize casing penetrations, eliminating external pipe spools

For HRSGs where transport and weight limitations allow, the main steel support structure is integrated and pre-fabricated with the boxes in a design that is the ultimate in constructability.

| Features | Benefits |

|---|---|

| Main support columns, top, side, and bottom casing attached to module box | No field installed insulation is required between “cold” boxes |

| Stub column provided to stabilize module when erected | No lifting frames required, only two moment connections per column line |

| Heating surface | Installed in module boxes |

| Module HARPS | Shop hydro tested |

Shop Installed:

• Gas baffles (except center gas baffles)

• Interconnecting piping between HARPS

• Most vent and drain piping

• Stainless steel metal bellows

• Expansion joints or seal plates

• Bumpers and guides (except in “hot” boxes)

• Cover plates at all ECS penetrations in top and bottom casings

Subject to shipping limitations. Same as MSG (2 & 3 Wide Applications)

THE SMART-BOX

SMART – Semi-Modular Accelerated Delivery Reduced Cost Top Supported. Use when shipping restraints prevent us from offering ECS.

SMART-Box features a high level of pre-assembly; modules, casing, interconnecting piping, and some structural steel all combined in one box, thereby drastically reducing the number of man-hours needed for erection. The modules are shop-assembled with top, side, and bottom casing attached for shipment. This option significantly reduces the amount of field labor needed to erect.

SMART Box Design Single Base Plate on all HRSG Columns –Welded in Shop Lifting Beams Furnished on All Boxes Increased Space Between Boxes for easier Fit-up Shop Installed Attic & Basement Baffles Welded Connections for all Temporary Diagonal Shipping Steel Reduced the amount of Field installed Baffles Simple Connection for Vent & Drain Piping Between Boxes Collection Headers in Evaporator Sections (if Feasible)

| Features | Benefits |

|---|---|

| Top, side, and bottom casing attached to module box | No field installed insulation required between “cold” boxes |

| Stub column provided to stabilize module when erected | No lifting frames required |

BUNDLE DESIGN

The Bundle features a high level of pre-assembly and come with the following items shop installed; modules, top casing, hanger rod support system, internal attic baffles, roof casing penetration seals and interconnecting piping. The redesigned bundle now has the following features: minimization of the removal of shipping steel, provides an option for a single crane lift if the site requires, the modules are immediately top supported once set in place and the total linear feet of external seal welding on the casing when the columns are attached to the casing are reduced. The bundle design also allows the erector to start setting the structure and casing prior to the arrival of pressure parts.

LOOSE HARP DESIGN

In cases where site access is limited, the Loose Harp reduces the pre-assembly process. The design includes individual module harps that can be transported to the site using normal road transportation. This solution saves time and money.

Easier to Ship and Handle, Lower Equipment Price, Earlier Delivery, More Site Work Required, Smaller Crane Required.

| Features | Benefits |

|---|---|

| Loose HARP |

|

| Installation of Module HARPS, all interconnecting vent and drain piping, gas baffles, SS metal bellows expansion joints |

|

Design Solutions for All Your Heat Transfer Equipment

Steam Surface Condenser

Our condenser designs can incorporate enhanced deareation systems, and/or a variety of turbine exhaust options, which can assist in improving plant layouts. We continually address and refine these and other considerations associated with circular designs where space is at a premium. The surface condenser is a critical component in the operation of a steam power plant. Condenser failures can result in forced outages and loss of generation capacity. TEi condensers represent an evolution of advanced technology, offering improved thermal efficiency and advanced mechanical design to reduce forced outages and increase availability.

Steam Surface Condenser Modular Changeouts

As the innovator in heat transfer technology, TEi provides exceptional modular changeout options for steam surface condensers. Modular changeouts are an efficient alternative to the conventional retube. Existing condensers can be refurbished, redesigned, and even upgraded to meet new performance demands and power requirements. Complete surface condenser retrofits are possible and can offer a multitude of benefits. A surface condenser is critical to the efficient operation of a power plant.

Low Pressure Feedwater Heater

Each feedwater heater can extract up to 30% of the turbine throttle steam and is designed to specific thermal conditions and manufactured for a singular purpose. The low pressure feedwater heaters play a key role in maintaining efficient, trouble-free operation of your generation facility and the vertical channel down (VCD) designs offer a small footprint, piping economics and simplified bundle access.

High Pressure Feedwater Heater

TEI’s feedwater heaters are each designed to specific thermal conditions and manufactured for a singular purpose. Whether it be sophisticated designs involving extreme superheat, abnormal flow conditions or dissipation of high energy fluids, TEi has the expertise and experience to offer proven solutions to any design problem. TEi provides innovative and practical concepts to ensure peak heater performance from installation to testing through full or part-load operation. We offer a multitude of design configurations for desuperheater and drains cooler zones as well as the latest in channel closure techniques. The three most common are listed below:

- Bolted-Gasketed Closure – This economical, gasketed pill box is easily disassembled for full access.

- Seal-Welded Diaphragm Closure – This economical welded closure is leak-proof and easily disassembled for full access. It requires no gaskets.

- Breech-Lock Closure – This widely accepted, quick opening closure provides full access to the tubesheet and structural reliability under varying temperature and pressure conditions.

Fuel Gas Performance Systems

TEi’s GT Fuel Gas Performance Heater Control packages are designed site-specific to provide heated gas at optimal temperatures for the GT operation. TEi’s packaged heaters are also designed to eliminate excess moisture that may otherwise condense in the gas turbine combustor.

Gland Steam Exhaust Condensers

Operating costs can be reduced with TEi’s Gland Steam Condenser by optimizing turbine gland steam cooling/condensation. Skidded assembly of blowers, piping, and valves allows for easier installation and immediate service. Conforms to all international standards and meets stringent vibration, noise, and performance requirements.

Heat Exchangers

Closed Cycle Cooling Water (CCW) HX

TEi has successfully supplied numerous optimized BOP and CCW designs for numerous fossil and nuclear power plants undergoing power up-rates and routinely provides solutions for power plants needing to improve efficiencies. With diverse high-quality applications, impressed current & galvanic anodic protection, elimination of potential cross-contamination of fluids, compact construction when designing for fluids with high thermal resistances and can be externally and internally applied, TEi’s mission-critical equipment helps ensure a stable, optimal operating temperature while reducing costs and dramatically improving efficiencies for our customers.

CCW Heat Exchanger

Generator Cooler HX

TEi’s Generator Engine Coolers cool air or hydrogen, which in turn cools the internal components of the motor or generator. These coolers are available in single tube, double tube, plate-fin and fin-tube designs.

Lube Oil Cooler HX

The lube oil cooler is to maintain oil temperature of the turbine lube oil by utilizing cooling water through the tubes. TEi provides shell & tube TEMA type heat exchangers for this service.

Rotor Air Cooler / Kettle Boiler HX

Our Shell & Tube Rotor Air Cooler Kettle Boiler Heat Exchangers are used to cool gas turbine rotor cooling air in a Combined Cycle Power Plants. The rotor air heat is tranferred to the water on the shell side, which is converted to steam and piped into the HRSG. The recovery of waste heat produces a netr increase of the CCPP efficiency. The RACKB’s can be purchased with or without controls and instrumentation. Controls and Instrumentation options include, control valves, bypass lines, drain tank, Temperature and Pressure monitors/transmitters, heat tracing, PLC. Materials of construction include options for carbon steel, 304SS, 316 SS, Incoloy and Inconel.

Fuel Gas HX

Our shell and tube fuel gas performance heat exchangers are used to heat natural gas that is fed to the gas turbines. They can be purchased with or without controls and instrumentation. The options include control valves, bipass lines, drain tank, temperature and pressure monitors/ transmitters, heat tracing, PLC.

Top People, Regional Locations, We Deliver

TEIC leads the industry with more than 20 years experience in providing direct-hire, on-site construction services for the installation, repair, alteration and maintenance of HRSG equipment nationally.

- HRSG Erection

- Environmental Control Systems

Babcock Power companies also provide a wide variety of services to keep you running including inspections, engineering studies and modeling, turnkey retrofits, spare parts and more. Click here to view our aftermarket services.